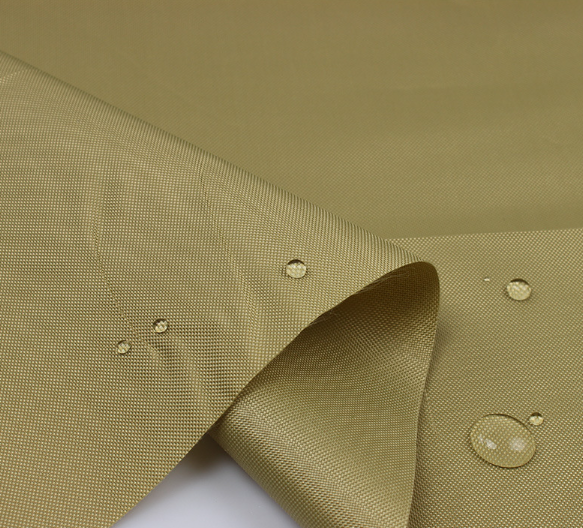

Oxford fabric is a woven textile characterized by its distinctive basket-weave structure, typically produced using thicker yarns for the warp and finer yarns for the weft. This construction creates a fabric that balances strength, flexibility, and breathability. Oxford fabric can be made from various fibers, including polyester, nylon, cotton, or blended yarns, with polyester Oxford fabric being the most common choice for outdoor applications.

The weave structure gives Oxford fabric a slightly textured surface and inherent resistance to tearing compared to plain weaves. Its adaptability to coatings and finishes makes it a popular base material for functional outdoor textiles such as backpacks, tents, outdoor furniture covers, and protective equipment.

Is Oxford Fabric Naturally Waterproof

Oxford fabric is not naturally waterproof by default. The woven structure allows water to pass through the gaps between yarns unless additional treatments are applied. However, this does not limit its outdoor potential, as Oxford fabric is specifically designed to accept waterproof and water-resistant coatings.

In outdoor products, Oxford fabric is almost always treated with a surface coating or backing layer. These treatments transform the fabric from a basic woven textile into a functional barrier capable of resisting rain, splashes, and moisture exposure in real-world outdoor environments.

Common Waterproof Treatments Used on Oxford Fabric

The waterproof performance of Oxford fabric depends largely on the type and quality of coating applied. Different treatments provide varying levels of water resistance, durability, and flexibility, making them suitable for different outdoor uses.

- PU coating, offering good waterproofing, softness, and cost-effectiveness

- PVC coating, providing higher waterproof levels and abrasion resistance

- TPU coating, combining waterproofing with flexibility and cold resistance

- DWR surface treatment, allowing water to bead and roll off the surface

For heavy-duty outdoor use, Oxford fabric often combines a base coating such as PU or PVC with a DWR finish on the surface, creating layered protection against moisture.

Understanding Waterproof Ratings in Outdoor Oxford Fabric

Waterproof performance is commonly measured using a hydrostatic head rating, expressed in millimeters. This rating indicates how much water pressure the fabric can withstand before leaking. Oxford fabric used outdoors can range widely in waterproof rating depending on its coating.

| Waterproof Rating | Typical Outdoor Use |

| 500–1000 mm | Light rain covers, casual outdoor bags |

| 1500–3000 mm | Backpacks, tents, outdoor furniture covers |

| 3000 mm and above | Heavy rain protection, professional outdoor gear |

For most outdoor scenarios, Oxford fabric with a waterproof rating above 1500 mm is considered reliable enough to handle sustained rainfall and wet conditions.

How Durable Is Oxford Fabric for Outdoor Environments

Durability is one of the key reasons Oxford fabric is widely used outdoors. Its basket weave structure enhances tear resistance, while the use of synthetic fibers like polyester or nylon provides excellent tensile strength and abrasion resistance. This makes Oxford fabric suitable for environments where repeated friction, folding, and tension occur.

Outdoor Oxford fabric is often rated by denier, such as 210D, 420D, 600D, or 900D. Higher denier fabrics use thicker yarns, resulting in greater strength and resistance to wear. For example, 600D Oxford fabric is commonly used for backpacks and outdoor covers due to its balance of durability and weight.

Resistance to UV Exposure and Weathering

Outdoor materials are constantly exposed to sunlight, temperature changes, and environmental stress. Oxford fabric made from polyester typically offers better UV resistance than nylon, making it more suitable for long-term outdoor exposure.

Many outdoor-grade Oxford fabrics include UV stabilizers or special finishes to slow color fading and fiber degradation. This helps maintain both appearance and structural integrity over extended use in outdoor conditions.

Abrasion and Tear Resistance in Practical Use

Oxford fabric performs well in applications where surfaces rub against rough ground, metal frames, or equipment edges. The weave distributes stress across multiple yarns, reducing the risk of sudden tearing. This makes it suitable for camping gear, tool bags, and protective outdoor covers.

Panel-like fabrics with plain weaves may fail more quickly under the same conditions, while Oxford fabric maintains functionality even after repeated abrasion.

Breathability Versus Waterproof Performance

One important consideration for outdoor use is the balance between waterproofing and breathability. Oxford fabric with heavy PVC coatings offers excellent waterproof protection but limited breathability. This is suitable for covers and storage applications but less ideal for clothing.

For outdoor apparel or soft gear, PU-coated Oxford fabric or fabrics with breathable membranes provide a compromise, offering water resistance while allowing some moisture vapor to escape.

Common Outdoor Applications of Oxford Fabric

Oxford fabric is widely used in outdoor products where waterproofing, durability, and cost efficiency are required. Its versatility allows manufacturers to tailor fabric specifications to specific use cases.

- Backpacks, travel bags, and hiking gear

- Tents, awnings, and camping accessories

- Outdoor furniture covers and equipment protection

- Tool bags and industrial outdoor storage

How Oxford Fabric Compares to Other Outdoor Fabrics

Compared to canvas, Oxford fabric is lighter and dries faster, while offering comparable durability when properly coated. Compared to ripstop nylon, Oxford fabric provides better abrasion resistance but slightly less tear propagation control.

These trade-offs make Oxford fabric a practical middle-ground solution for many outdoor products where performance, weight, and cost must be balanced.

Maintenance and Care for Outdoor Oxford Fabric

Proper maintenance extends the waterproof and durable performance of Oxford fabric. Regular cleaning removes dirt that can degrade coatings and fibers over time. Mild soap and water are usually sufficient for most outdoor items.

Reapplying DWR sprays or waterproof treatments can restore water repellency after prolonged use. Avoid excessive heat or harsh chemicals, as these can damage coatings and reduce fabric lifespan.

Is Oxford Fabric Suitable for Long-Term Outdoor Use

When properly specified and treated, Oxford fabric is both waterproof and durable enough for long-term outdoor use. Its performance depends on fiber type, denier, coating method, and environmental exposure. For many outdoor applications, it offers an excellent balance of protection, durability, and affordability.

Understanding these variables allows users and buyers to select the right Oxford fabric for their specific outdoor needs, ensuring reliable performance in real-world conditions.

English

English

中文简体

中文简体